Metal Storm multi-shot grenade launcher (Australia)

Diagram of the Metal Storm 40mm 3-shot grenade launcher, mounted above the F88 (Steyr AUG) rifle.

Note the electronic fire control module, loaced in the butt of the rifle.

Caliber: 40mm (others possible)

Type: stacked-projectile, caseless multishot system

Overall length: n/a

Weight: n/a

Effective range: up to 400 m

Capacity: 3 shots (current 40mm model, single barrel)

Type: stacked-projectile, caseless multishot system

Overall length: n/a

Weight: n/a

Effective range: up to 400 m

Capacity: 3 shots (current 40mm model, single barrel)

The Metal Storm grenade launching system is a radical step from most conventional firearms. Using the ancient principle of an "Roman candle", Metal Storm weapon systems currently are promoted in a variety of calibers and applications. One of such applications is the 40mm, multi-shot grenade launcher, that could be either mounted on the infantry rifle to create an enchanced-capability infantry weapon like the Australian AICW system, or to be mounted on stationary or vehicle platforms in multi-barrel configurations.

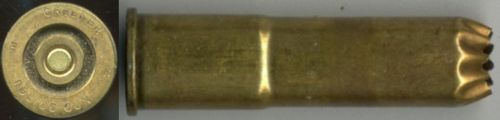

Key advantage of Metal Storm system is its mechanic simplicity. In fact, the standard Metal Storm grenade launching unit is no more than a single rifled barrel, loaded with several projectiles, stacked one upon the another. There are no loading mechanisms, no feed units nor magazines or belts - each barrel is a magazine itself. Projectiles are fired using powder charges, located in the hollow hase of each projectile, and there's no case left to extract and eject after each shot;Powder is ignited by the electric ignition system, wired to the electrinic fire control module through small ports in the wall of the barrel. When user press the firing button or trigger, electronic fire control module sends the ignition impulse to the charge of the foremost projectile in the stack; when trigger is pressed for the second time, module ignites the second charge and then next, until barrel is empty. Once all the rounds in the barrel are shoot out, it can be removed from the host and then either collected and later sent to factory for reloading, or simply discarded.

Current 40mm grenade launching module, developed for the AICW rifle/GL system, contains three grenades stacked one in front of another in single barrel. Each barrel has an electronic interface which is connected to the fire control unit, built into the host platform. This is about the simplest systems, at least from the operator's point of view (from developer's point of view, there's plenty of complications and difficulties, most of which seems to be already overcome).However, there is one drawback when Metal Storm system is compared to existing mechanically or manually reloaded systems - latter systems still can be fired once batteries are dry; Metal Storm always require some sort of electric power to operate. This problem may seem critical, especially for military purposes, but, actually, it is not. For example, several Soviet/Russian anti-tank grenade launchers (like RPG-16 orRPG-29) are built using electric rocket ingnition; necessary electricity is provided by the magneto-impulse generators, powered by the pull of the trigger. Same idea also could be possibly applied to the Metal Storm system.

Current 40mm grenade launching module, developed for the AICW rifle/GL system, contains three grenades stacked one in front of another in single barrel. Each barrel has an electronic interface which is connected to the fire control unit, built into the host platform. This is about the simplest systems, at least from the operator's point of view (from developer's point of view, there's plenty of complications and difficulties, most of which seems to be already overcome).However, there is one drawback when Metal Storm system is compared to existing mechanically or manually reloaded systems - latter systems still can be fired once batteries are dry; Metal Storm always require some sort of electric power to operate. This problem may seem critical, especially for military purposes, but, actually, it is not. For example, several Soviet/Russian anti-tank grenade launchers (like RPG-16 orRPG-29) are built using electric rocket ingnition; necessary electricity is provided by the magneto-impulse generators, powered by the pull of the trigger. Same idea also could be possibly applied to the Metal Storm system.

09.08

09.08

Jack The Ripper

Jack The Ripper